India’s defence manufacturing sector is witnessing unprecedented momentum, and West Bengal is positioning itself as a major player in this transformation. With an impressive 90 lakh Micro, Small, and Medium Enterprises (MSMEs) forming the backbone of its industrial ecosystem, the state is making bold moves to capture a significant slice of the defence manufacturing pie. But can this eastern powerhouse truly deliver on its ambitious promises?

The Numbers Game: Bengal’s Industrial Muscle

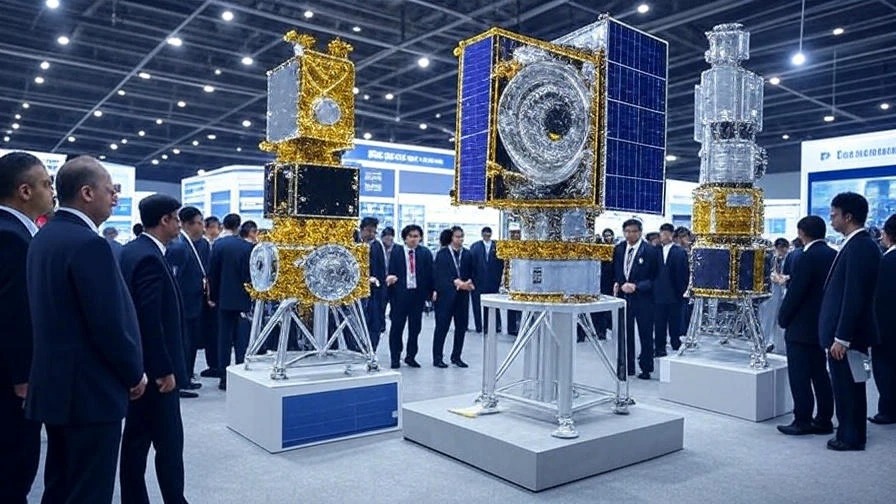

The statistics are staggering. West Bengal boasts one of India’s largest MSME bases with 90 lakh units, representing a vast reservoir of entrepreneurial talent and manufacturing capability. To put this in perspective, this single state houses more MSMEs than many countries have businesses altogether. The recent Defence MSME Manufacturing Forum in Kolkata, organized by the Indian Chamber of Commerce, highlighted this untapped potential.

Rajesh Pandey, Principal Secretary for MSME and Textiles, emphasized how this massive network could serve as a flexible supply chain for defence components, sub-assemblies, and specialized equipment. The timing couldn’t be better – the Ministry of Defence has explicitly stated its intention for MSMEs and startups to participate “in a big way” in the defence sector, creating a perfect storm of opportunity.

Beyond Numbers: Infrastructure and Commitment

Bengal’s advantages extend beyond mere statistics. The state already houses significant industrial infrastructure, including one of India’s largest leather parks – a sector that could contribute to various non-metallic defence components. A Rubber Park is under development, and several other industrial parks are operational, providing the necessary ecosystem for defence manufacturing.

What sets Bengal apart is its government’s proactive approach. A high-powered committee meets every 15 days to monitor project progress, demonstrating serious commitment to facilitating investment. Pandey’s invitation for “across-the-table interactions” to understand investor requirements signals an adaptive, responsive approach to attracting defence manufacturing investment.

The forum saw participation from senior officials of key defence entities including GRSE, Bharat Dynamics Ltd, Hindustan Aeronautics Ltd, and Titagarh Wagons. This industry presence underscores genuine interest and potential for meaningful collaboration.

The Eastern Handicap: A Critical Challenge

However, the path ahead isn’t without significant roadblocks. Former Indian Air Force chief Air Chief Marshal Arup Raha raised a crucial concern at the forum – the absence of a dedicated defence corridor in eastern India. While two such corridors have been approved in regions “which have plenty,” eastern and northeastern India have been “totally ignored” despite their immense potential.

This imbalance represents more than just geographical unfairness. Defence corridors provide integrated infrastructure, specialized facilities, and policy support that are essential for competitive manufacturing. Without such dedicated central support, Bengal might struggle to attract the scale of investment needed to compete with established defence manufacturing zones in other parts of the country.

Raha’s call for regional governments to collaborate with the centre for an eastern defence corridor highlights a fundamental policy gap that could limit Bengal’s defence manufacturing aspirations.

The Technology Trap

Another significant challenge emerges from India’s broader technological limitations in defence manufacturing. Raha pointed out India’s dependency on foreign suppliers for critical components like jet engines, citing the purchase of General Electric F404 and F414 engines for LCA Tejas variants. Despite contracts, “the Americans wouldn’t give you the core technology,” he noted, highlighting a fundamental weakness in achieving true defence self-reliance.

While MSMEs may not directly manufacture jet engines, their eventual role in supplying sophisticated components for high-tech defence systems will require advanced capabilities. This national technological gap presents a long-term challenge for MSMEs aspiring to move beyond basic manufacturing into more complex defence production.

The Micro Challenge

Perhaps the most significant hurdle lies in the composition of Bengal’s MSME base itself. With 99% of the 90 lakh units classified as micro enterprises, there’s a fundamental scaling challenge. Micro units often face limitations in capital investment, access to advanced machinery, quality control standards, and obtaining necessary certifications for defence manufacturing.

The rigorous demands of defence production – from precision engineering to stringent quality standards and complex certification processes – require capabilities that most micro units currently lack. Bridging this gap will need substantial policy support, skill development programs, and financial assistance to help these units upgrade and integrate into sophisticated supply chains.

The Verdict: Promise Versus Reality

Bengal’s defence manufacturing ambitions represent both tremendous opportunity and significant challenges. The state’s massive MSME base, proactive government approach, and existing industrial infrastructure create a strong foundation. The alignment with national policy and industry interest adds credibility to these aspirations.

However, the absence of a dedicated eastern defence corridor, technological limitations, and the predominance of micro units present substantial hurdles. Success will depend on addressing these systemic challenges through sustained collaboration between state government, central government, and private industry.

The transformation won’t happen overnight. Converting micro enterprises into defence-ready manufacturers requires time, investment, and comprehensive support systems. While the potential is undeniable, execution will determine whether Bengal’s defence manufacturing dream becomes reality or remains an ambitious aspiration.

For investors and industry watchers, Bengal’s defence manufacturing story represents a compelling case study in industrial transformation. The state’s efforts deserve attention, but expectations should be tempered with realistic assessments of the challenges ahead.

Disclaimer

This analysis is for informational purposes only and should not be considered as investment advice or recommendation. The defence manufacturing sector involves significant risks and regulatory complexities. Readers are strongly advised to conduct thorough due diligence and consult qualified professionals before making any investment decisions. Past performance and government initiatives do not guarantee future results or success.